Textrol Laboratories

Products

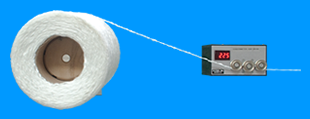

Tension Deviation Control System (TDCS)

The patented TDCS system is a tension monitoring and correction system for strand yarns with a closed loop/feed back control. The device utilizes an electromagnetic brake module to increase or relieve tension to the strand as it is monitored by the roller transducer mechanism. The transducer roller has the ability to flex while the other roller (or rollers) are stationary. It is the monitoring of this deflection by the internal transducer beam that allows the detection of any change of tension in the yarn path. The transducer sends a constant control signal to the brake module to maintain a desired tension set point.

The Tension Deviation Control System is capable of precise strand tension control for a large variety of yarns and/or wire without damage to the product due to the slip free grip of the durable plastic carrier. All known strand materials have been handled successfully including natural, man made and blended yarns: spun yarns, mono filaments, elastic yarns, aramid fibers, fiberglass, carbon filaments, elastic fibers, as well as copper, gold, platinum, stainless steel and aluminum wire.

Tangential Brake in Closed Loop System

Tangential Brake in Closed Loop System

The TDCS units are unaffected by incoming yarn tension variations from the package: full to empty. They are also unaffected by package transfers, yarn finishes, textures or twist. A TDCS unit can be configured as stand alone or in any multiple end system requirements.

Tension ranges can be as low as 5 grams or as high as 2500 grams depending on the required output tension of the customer. Typical tension uniformity and repeatability is +/- 1% of the tension set point. Note: the tension set point of the TDCS must be set slightly higher than that of the take off tension of the package (approximately 5 grams).

Standard TDCS Tension Ranges: Custom ranges are available along with custom sizes up to 2500g.

- 5g to 60g

- 10g to 100g

- 20g to 200g

- 30g to 300g

- 50g to 500g

- 75g to 750g

- 100g to 1000g

- 150g to 1500g

In addition to precision tension control, the TDCS has a built in stop motion feature. Any broken end or package run-out will be quickly detected and a signal will be sent to stop the machine. The Tension Deviation Control System has a light that illuminates so that the location of the lost end can be found easily. The monitored tension is displayed directly on the unit!

The TDCS can be supplied with or without pretensions, pigtail or ceramic strand guides and various other accessories. The strand can enter the carrier from many directions but must maintain at least 270° of contact with the carrier to prevent slippage as well as enter the first transducer roller with good contact.

The standard duty TDCS unit has a two roller transducer set-up. The heavy duty TDCS (1000 grams and up) will have a 3 roll set-up. The TDCS is normally used in a horizontal arrangement (in relation to the floor) but can be calibrated to be used in a vertical application as well!

Electromagnetic Tension Devices & Accessories

- Accutense

- Accumeter / Accupulse

- Tension Deviation Control System (TDCS)

- Tangential Brakes

- Tension Meters

- Controllers / Power Supplies

Permanent Magnet Tension Devices

Yarn Measuring and Tensioning